|

Toy Trucker &

Contractor

|

|

Build A 1913 Ford Delivery Van by Richard Marmo

In Fort Worth, Texas in 1913, at least some roads were paved, streetcars and interurban cars were in their heyday while horsedrawn delivery wagons were on the decline. Motorized delivery vans, in the form of customized bodies mated to the chassis of various automobile manufacturers….frequently ones produced by Ford…were more and more common. Whatever the product was, you more often than not would see the brand name prominently lettered on the side of the delivery van. As with today, you never had to wonder when someone was transporting Coca-Cola products. Even in 1913, Coke was definitely the real thing!

Several decades ago, Bandai produced a series of 1/16th scale automobiles, including several early Ford versions. Among them was a 1913 Ford Delivery Van with a choice of markings that included, wonder of wonders, a set of decals for Coca-Cola. Eventually the kits ceased production but were repopped by Entex. Sadly, they also went out of production after a period of time, but they can still be found on ebay. Most of the time, the kits will go for $150 - $200 and more, but if you’re persistent, patient and lucky, you can occasionally pick one up for $35 or so. Thanks to that combination and the invaluable assistance of a fellow IPMS/USA member, Mark Aldrich, I got my hands on one. Now let’s see what it takes to build the little puppy.

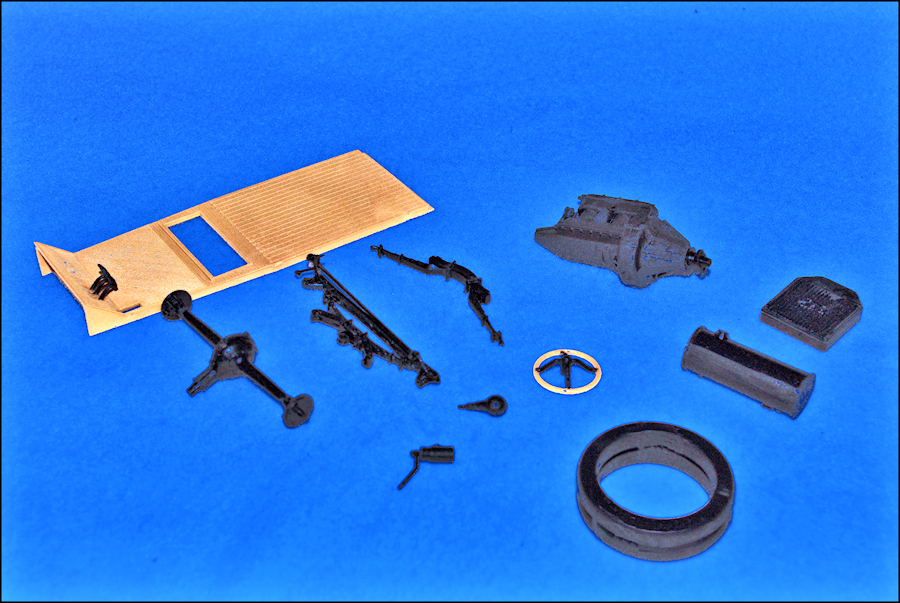

Before you start joining parts, be aware of one thing…you can’t build it according to the instructions. This kit and, by association, all of the 1/16th Bandai/Entex car kits have problems of one kind or another. Now that you’ve been warned, construction begins with the engine. While everything in that area was pretty straightforward, I ran into one problem that can occur when buying kits off ebay. It turned out that whoever had the kit before me had done some minor assembly, notably the engine. Aside from some sloppy building techniques that I had to correct, four clamps on the right side of the engine had been installed and then removed. They were nowhere to be seen. If I had been planning on doing a detailed engine, that would had been a problem. But between the inherent kit problems and a very short deadline (I had slightly over a month to build the model and write the article while building a helicopter model for a client in the same time period), I wasn’t. As many other components were assembled at the same time as was practicable, mainly the rear axle/differential, rear springs, front spring/axle, radiator, gas tank, etc. After giving the engine a shot of Model Master Steel, attention turned to the frame assembly…and that’s where things really got interesting. |

|

| Return to home page | |

|

|

|